Brakes are your last line of defense, so a repair is more than new pads. A safe, lasting fix starts with a complete picture of the system, from pedal to rotor.

Here is the structured checklist our technicians follow so your car stops straight, quiet, and predictably in all conditions.

Confirm The Concern And Road-Test For Symptoms

Before a wrench turns, we verify what you feel: squeal at low speed, a shudder on highway stops, a pull to one side, or a pedal that grows long at lights. A short road test maps when it happens, hot or cold, gentle or hard braking, and whether ABS activates early. Clear notes here point us to the right axle and save time.

Measure Pad Thickness, Rotor Condition, And Runout

Pads are measured on the inner and outer sides of each caliper. Uneven wear across the same axle signals a sticking slide or piston that new pads alone will not solve. Rotors are checked for minimum thickness and surface condition. We measure lateral runout with a dial indicator and compare it to spec, because excess runout becomes thickness variation and the shudder you feel two weeks later.

Free, Clean, And Lubricate Caliper Hardware

Slides must move smoothly and evenly. We remove rust scale from brackets, replace abutment clips, and use the correct high-temperature lubricant sparingly where specified. Caliper pins are inspected for straightness and pitting; boots are checked for tears that let water in. On fixed calipers, we verify equal piston retraction so pads do not drag and overheat.

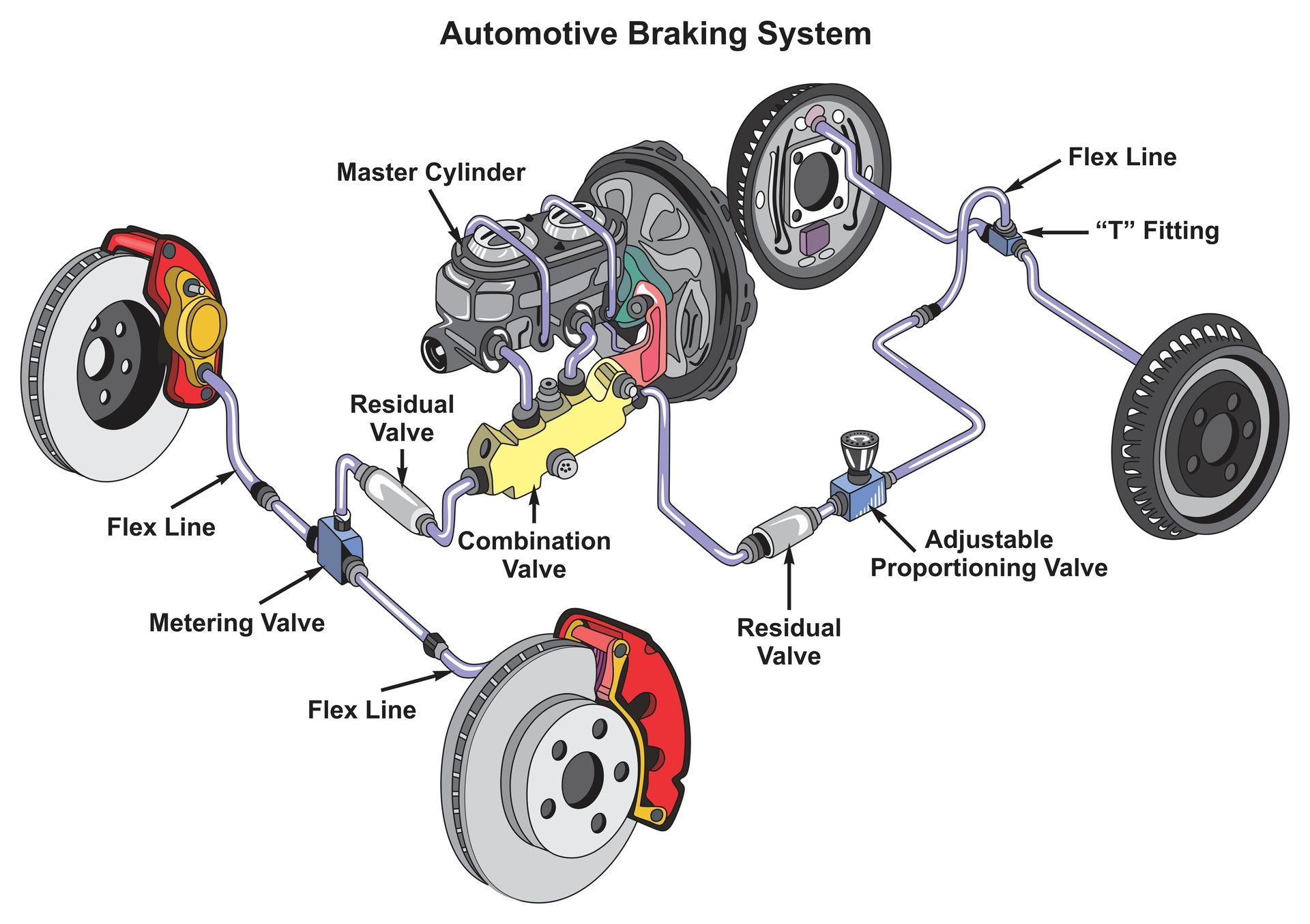

Inspect Hoses, Lines, And Fluid Condition

Flexible hoses can swell internally and act like a check valve, causing a pull or a dragging brake. Steel lines are checked for corrosion at clips and bends. Brake fluid is tested for moisture content, then flushed if it is beyond limits or discolored. Fresh fluid raises the boiling point, protects ABS valves, and gives a firm, predictable pedal under repeated stops.

Verify Parking Brake Operation And Adjustment

Whether your car uses a drum-in-hat rotor, an integrated electric caliper, or cables to shoes, the parking brake must apply fully and release cleanly. We inspect shoes and hardware on drum-in-hat systems, set correct clearances, and put electronic parking brakes into service mode to prevent damage during pad replacement.

Evaluate Wheel Bearings, Suspension, And Tire Factors

Brake complaints often trace to nearby parts. We check wheel bearings for play or roughness that can mimic rotor problems. Control arm bushings, ball joints, and tie rods are inspected because looseness here causes pulls and shakes under braking. Tires are measured for tread depth and even wear; cupping and flat spots create noises easily confused with rotor issues.

Service Rotors The Right Way For Your Vehicle

Some rotors should be replaced when pads are due; others can be refinished if the thickness allows and the vehicle maker approves. We clean hub faces to bare metal, measure runout after mounting, and index rotors if needed to meet spec. New rotors are degreased thoroughly so pads bed against clean iron, not packing oil.

Bed-In Procedure And Post-Repair Verification

Fresh pads and rotors need a controlled break-in to transfer an even film. After installation, we perform staged stops to seat the set, then recheck pedal feel, wheel temperatures, and ABS operation. A second road test confirms straight, quiet stops and stable pedal height. You get torque specs and measurements on your final report.

Quick Road-Test Checks You Can Do Safely

- Find An Empty, Straight Road And Make Several Medium Stops From 35–40 mph; note any steering shake or pull.

- After A Normal Drive, Coast To A Stop With the Windows Down; listen for light scraping or chirps that persist warm.

- Park, Then Carefully Feel For Heat Near Each Wheel (Without Touching Rotors); one corner much hotter hints at drag.

- On A Mild Slope, Test The Parking Brake; it should hold firmly and release without noise.

Stop With Confidence At Annie’s Auto In Ohio

If you feel a shake, hear new brake sounds, or see a warning light, we can pinpoint the cause and fix it right the first time. Our technicians follow this checklist on every brake job, then road-test and document results so your car stops straight and quiet.

Schedule a brake inspection with Annie’s Auto in Ohio and drive away with a firm pedal and peace of mind.

- Cleveland, OH 44130

- Brunswick, OH 44212

- Avon, OH 44011

- Cleveland, OH 44102